PETROSLEEVE story

To work, the repair needed to be fast, and it needed to be permanent.

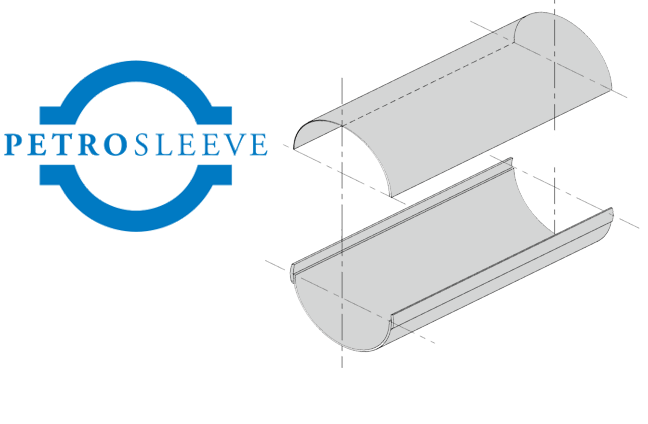

First conceived in the 1990s, the PETROSLEEVE® Pipeline Repair System is the result of many years of diverse and successful projects in pipeline integrity and pipeline construction completed by Petro-Line Upgrading Services Ltd.

Services

We deliver a Full Product Line, Training, Installation Services and, Engineering and Consulting Services.

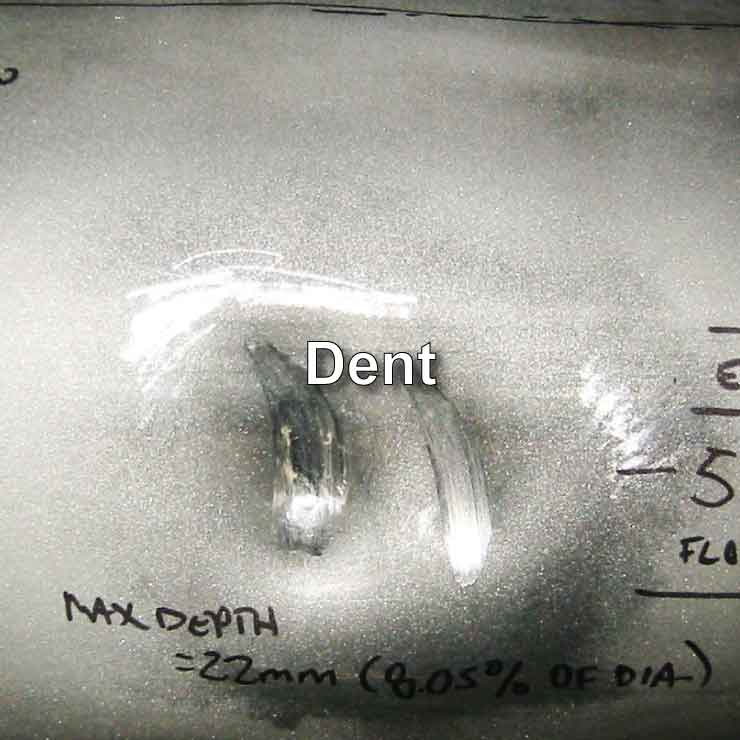

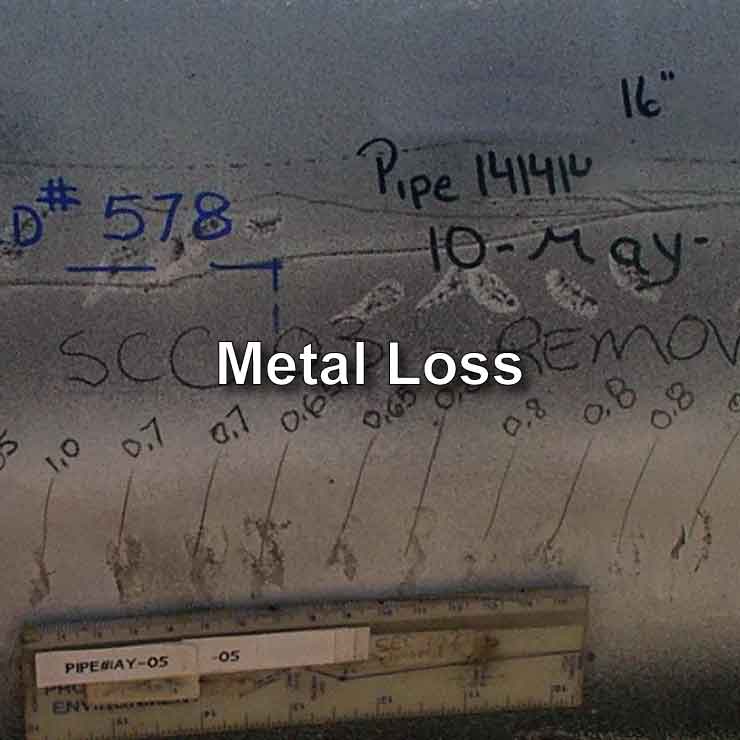

Defect Repair Details

Over 30,000+ PETROSLEEVE® repairs worldwide.

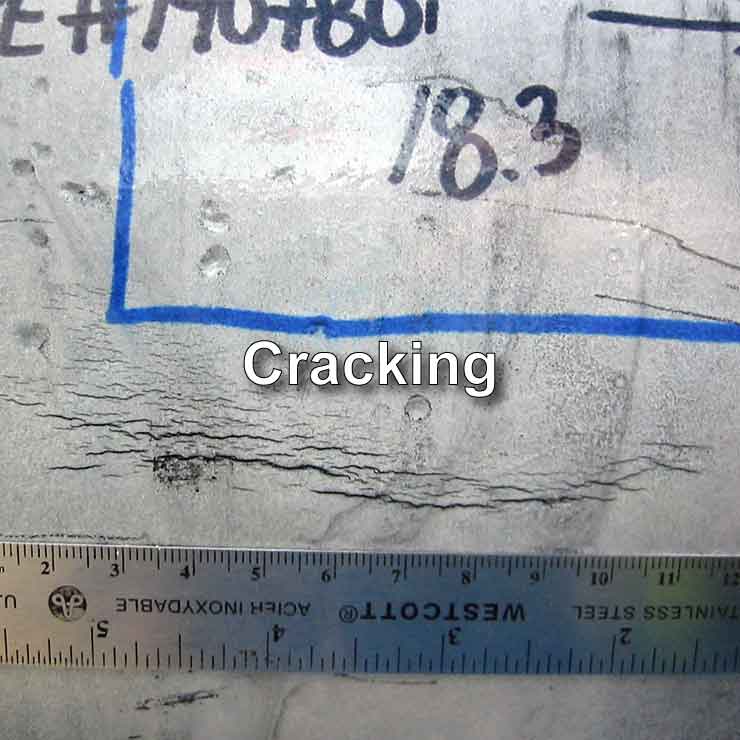

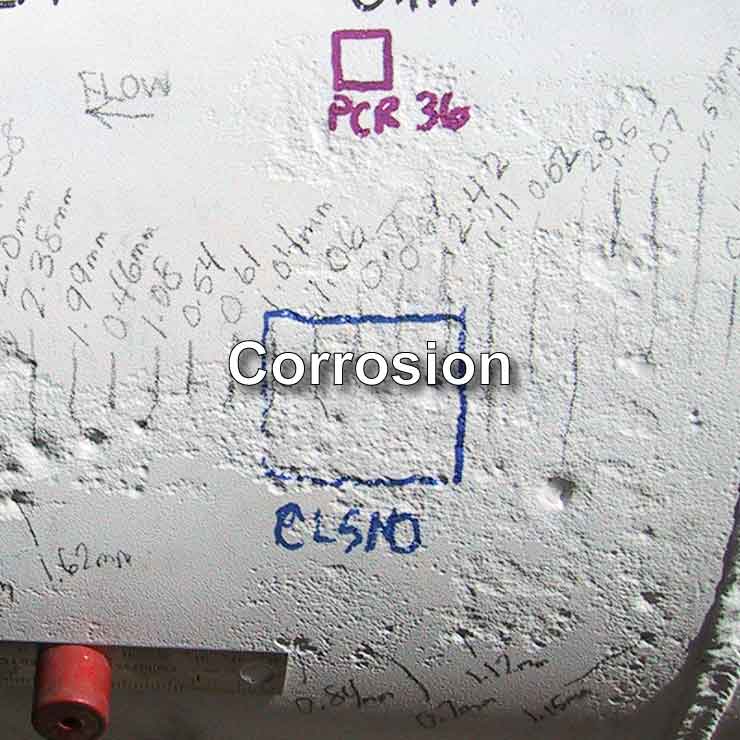

The PETROSLEEVE® delivers defect repair for Seam or Pipe Body Cracking, Corrosion, Dents, Mechanical Defects, SCC (Stress Corrosion Cracking), Manufacturing Defects, and Arc Burns.

The PETROSLEEVE® repaired area will exceed the life expectancy of a pipeline. Our clients welcome the surety our repair method offers as it reflects their desire to be good stewards of the environments we all value, and to protect them by insisting best practices are used in their construction, maintenance and repair.

After the installation of a PETROSLEEVE®, the pipeline owner can immediately confirm that their repair criteria has been achieved. You can have confidence in choosing the PETROSLEEVE® Pipeline Repair System as your pipeline repair method, knowing that zero failures have been reported for any installed PETROSLEEVE®.